Efficient and Practical Cupboard Woodworking Plans for Your Home

Hey there, fellow DIY enthusiasts! Are you dreaming of beautiful, custom-built cupboards that perfectly fit your space and style, but intimidated by the thought of tackling a woodworking project of this size? Don't be! Building your own cupboards is totally achievable, even if you're a beginner. With a little planning and these handy tips, you'll be amazed at what you can create. Let's dive into building some amazing cupboards together!

Planning Your Cupboard Project: The Foundation of Success

Before you even think about grabbing your saw, careful planning is key. This phase isn't just about aesthetics; it directly impacts the efficiency and success of your project. Rushing this step will almost certainly lead to frustration and rework later on.

1. Measuring and Designing Your Cupboards

Grab your measuring tape and get accurate dimensions of the space where your cupboards will go. Consider the height of your ceilings, the width of the wall, and any existing features that might influence your design. Sketch out a simple plan, noting the dimensions of each cupboard section. Will you have upper and lower cabinets? Will you need drawers? Thinking about these details beforehand is crucial.

2. Choosing Your Wood and Hardware

The type of wood you choose will greatly impact the look and durability of your cupboards. Plywood is a popular choice due to its strength and affordability. Solid wood like pine or oak offers a more luxurious look but can be more expensive. Consider your budget and desired aesthetic when making your decision. Don't forget about the hardware! Handles, hinges, and drawer slides are essential elements that affect both functionality and style. Choose these carefully and order them in advance to avoid delays.

3. Gathering Your Tools and Materials

This is where a detailed list comes in handy. You'll need a variety of tools, depending on your skill level and chosen design. At minimum, you'll need:

- Measuring tape

- Pencil

- Saw (circular saw or miter saw recommended)

- Drill

- Screwdriver (both Phillips and flathead)

- Sandpaper (various grits)

- Clamps

- Wood glue

- Wood screws

- Safety glasses

- Dust mask

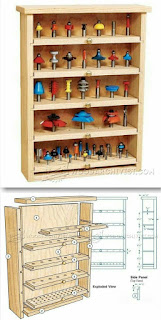

Beyond this basic list, you might need additional tools depending on your design. A router, for example, is excellent for creating detailed edges. Make a comprehensive list and check off each item as you acquire it.

Building Your Cupboards: A Step-by-Step Guide

With your plans finalized and materials gathered, it's time to get your hands dirty! Remember safety first – always wear safety glasses and a dust mask.

1. Cutting the Wood

Carefully cut your wood according to your plans. Accuracy is key here; even small errors can accumulate and affect the final look. Use a miter saw for precise cuts, especially for angles. If you are new to woodworking, practice your cuts on scrap wood first.

2. Assembling the Cabinet Boxes

Most cupboard designs involve assembling rectangular boxes. Use wood glue and screws to join the pieces. Clamps will be invaluable here to ensure strong, even joints while the glue dries. Take your time and work meticulously for the best results.

3. Adding Shelves and Drawers

Once the cabinet boxes are assembled, it's time to add shelves and drawers. Measure carefully and cut the wood to size. For drawers, consider using drawer slides for smooth operation. Properly fitting and aligning shelves and drawers can be tricky, so take your time and double check your measurements.

4. Installing Doors and Hardware

This is where your cupboards start to look like actual cupboards! Carefully attach the doors using hinges. Make sure the doors align properly and close smoothly. Once the doors are installed, attach the handles and knobs. This is a great time to step back and admire your handiwork!

5. Finishing Touches: Sanding and Staining or Painting

Sand all surfaces of your cupboards thoroughly to create a smooth finish. Start with coarser sandpaper and gradually move to finer grits. Then, you can either stain or paint your cupboards. Apply multiple thin coats for a professional look. Allow sufficient drying time between coats.

Installing Your Cupboards: The Finishing Line

The final step is installation. This can vary depending on your specific design and wall type. If you're attaching the cupboards directly to the wall, make sure to use appropriate wall anchors and screws.

1. Preparing the Wall

Ensure the wall is clean and level before installation. Use a stud finder to locate wall studs for added support.

2. Securing the Cupboards

Carefully position and secure your cupboards to the wall using screws or other appropriate fasteners. Use a level to ensure your cupboards are perfectly aligned.

Commonly Asked Questions

Q: What type of wood is best for kitchen cupboards?

A: Plywood is a popular and affordable choice for its strength and stability. Solid wood like oak or maple provides a more luxurious look and feel but is more expensive.

Q: How do I prevent wood warping?

A: Use properly seasoned wood and ensure adequate ventilation in the room. Avoid placing cupboards in areas with high humidity.

Q: Can I build cupboards without prior woodworking experience?

A: Absolutely! Start with a simple design and take your time. Plenty of online resources and tutorials can guide you through each step. Don't be afraid to ask for help from more experienced woodworkers.

Q: How long does it typically take to build cupboards?

A: The time required depends on the size and complexity of your project, as well as your woodworking skills. Simple cupboards might take a weekend, while more complex ones could take several weeks.

Q: What if I make a mistake?

A: Don't worry, everyone makes mistakes! Woodworking is a learning process. Take your time, measure twice, cut once, and don't be afraid to start over if needed. Remember, even professional woodworkers make mistakes.

Building your own cupboards is a rewarding experience that will enhance your home and your skills. With careful planning and these step-by-step instructions, you'll be well on your way to creating beautiful, functional storage solutions for your home! Happy building!